Free lifetime remote support on all products

Ask us about our discounts for education

The HBD-350 from best selling Selective Laser Melting machine (SLM) manufactures HBD, comes as a complete solution for your metal 3D printing needs. HBD are committed to becoming true experts in the metal additive manufacturing world. Optimising their SLM machines to work well with a variety of materials to ensure many applications can adopt this cutting edge technology and improve their part production. The larger build volume of the HBD 350 is specially optimised to fit most main stream moulding sizes. Challenging traditional manufacturing methods, the HBD SLM Machines raise the bar in all aspects of part production. A fully customisable system giving you full control over your SLM printer and its auxiliaries.

Compatible with a variety of materials including: Stainless steel, Cobalt-chrome alloy, Tool steel, Titanium alloy, High temperature alloy, Hastelloy, and some precious metals, HBD-350 is suitable for a diverse range of applications.

Three light indicators to easily show the different machine stages

HBD 350 is set on strong locking caster wheels, allowing the machine to be relocated easily then locked in place

Door open detection system, alerting the user when the door is open or closed, providing a crucial safety aspect to the process

Innovative systems. Atmosphere purification system which automatically monitors the oxygen content and recycles clean and collected air. High speed deoxygenation system which also includes high precision oxygen content monitoring

Easy access to the printing area with reduced powder exposure to yourself or the environment with the sealed powder hatch, allowing you to de-powder parts easily and add more powder if needed

Real time printing status showing you information including current layer, build parameters and many more

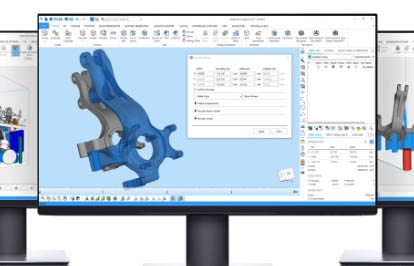

Use the industry standard Materialise Magic's software with your HBD System, available as part of the complete HBD system. Materialise Magics features intelligent slicing, printing checks and error detection, support generation, intuitive part orientation functions and many more

Intelligent powder feeding system automatically feeds powder from the top rather than the bottom, also features two way powder recoating

Ensure printing consistency with adjustable Z direction focus on the dual lasers, water and air cooled temperature control which maintains long-term stability

3D Printed Topology Optimised Aerospace Part

Materialise Magics Programming Software

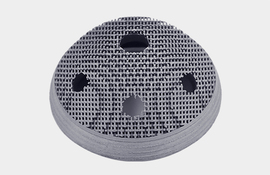

Mould & Die-Traditional manufacturing methods for ,oulds and dies cause uneven cooling due to geometric restrictions. SLM can produce more complex designs with conformal cooling chanels. These will achive fast, uniform cooling and better results in the end part. The build volume of HBD 350 is specially optimised for mould and die production, giving you a greater freedom in design and complexity of part geometry.

3D Printed Sprue Brush for Accepting Extrusion Nozzle

Aerospace- 3D Printing in aerospace allows for substantial weight saving. Parts can be manufactured with internal lattice structures to reduce weight and stress and improve stability and strength. Topology optimisation can be easily schieved with SLM technology. End use pars can be printed in one process compared to traditional manufacturing methods which require the production of moulds or tooling.

3D Printed Aerospace Housing Part

3D Printed Prostetic

3D Printed Bio-compatible Hip-Joint

SLM Technology offers an extensive range of material options. The HBD 350 can print both prototypes and end-use parts easily. By combining Materialise Magics into your HBD system you can programme builds efficiently by using their innovative features such as part orientation functions, Support creation, Part nesting checks, Intelligent slicing.

Tool Steel 18Ni300- Hardening steel characterised by high strength and high toughness. Easy to post process after printing. Applications- Mould Manufacturing, Industrial Components.

Chrome-Cobalt Alloy CoCrMo- A mix of pre-alloyed powders for printing. Excellent mechanical properties, resistance to corrosion and heat. Applications- Medical field, Turbines and aircraft engine parts, Parts requiring thin walls.

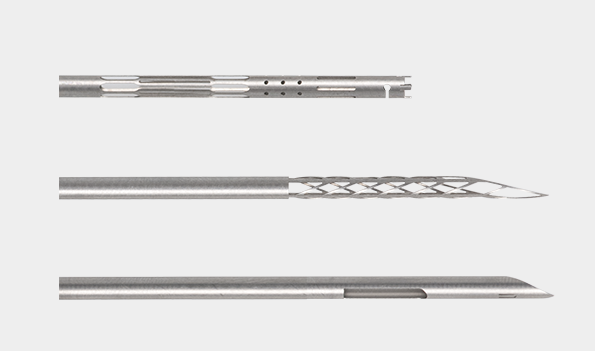

Titanium Alloy TC4- Lightweight alloy featuring good mechanical properties, corrosion resistant, good biological compatibility. Applications- Lightweight structures and components, Orthopaedic implants, surgical tools, guide plates.

Nickel Based Alloy Ni718- Good ageing and corrosion resistance. High temperature strength and fracture strength up to 700°C temperatures. Applications- Turbine components, Aerospace and Rocket components.

Stainless Steel 316L- High strength and corrosion resistance. Overall performance is better than 310 and 304 stainless steel. Applications- Personal products such as watches, jewellery, eyewear frames. Industrial parts in automotive, Marine industries.

AI Alloy AlSi10mg- Good properties for producing parts with thin walls and complex geometric designs. Significantly enhanced strength and hardness due to silicon/magnesium contents. Applications- Functional parts. Parts requiring high thermal performance.

3D Printed Motorbike Intake Part

Aerospace

Medical

Automotive

Mould making

Tailor your HBD SLM 3D Printer to your needs. See the list below for the additional options available for the HBD.

HBD-350 SLM 3D Printer

External purification system

Small laser chiller

Intelligent powder feeding system

Materialise Magics & HBD solutions build processor

HBD build expert

Process parameters

Parameter package editing and self built

Base plate

Filter

Flexible scraper

Sieving station

Powder drying oven

Vacuum cleaner

Heat treatment furnace

Sandblasting machine

Multi functional tool cart

Powder collecting tank

Warranty, Technical support, Training

3D Printed Mould