3D Printers

iMakr is proud to offer one of the widest ranges of additive manufacturing solutions in the world. Featuring globally recognised brands and the latest technology, you are guaranteed to find the ideal 3D printer to suit your industry or application.

Not sure which is the right solution for you? Speak with one of our advisors and let us help you to find the perfect machine for your application and budget.

Nexa3D XiP

The XiP from Nexa3D is an ultrafast desktop resin 3D printer, combining a small, compact footprint with a generous 4.8L build volume. Create prototyping and production-grade components for engineering, dental, medical, education, and other applications faster than ever before.

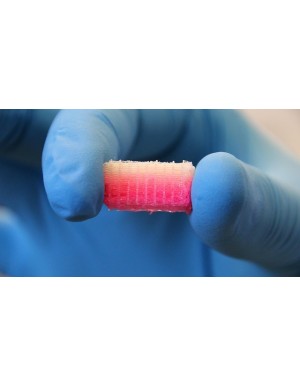

EnvisionTEC 3D-Bioplotter

Anisoprint Composer A4

Reduce the cost and weight of jigs, fixtures and end-use parts, while maintaining mechanical properties, with the Composer A4 from Anisoprint.

Unique Composite Fibre Coextrusion (CFC) technology allows the printing of continuous carbon fibre directly into a 3D printed part, significantly increasing part strength when compared with printing polymers alone.

Nexa3D NXE 400

HBD-150 Metal 3D Printer

The HBD-150 is a Selective Laser Melting machine (SLM) capable of printing in a variety of materials. A fully customisable system giving you full control over your SLM printer and its auxiliaries whilst still being an affordable entry point for SLM technology. Contact iMakr to find out how we can tailor your HBD-150 for you.

Anisoprint Composer A3

Reduce the cost and weight of jigs, fixtures and end-use parts, while maintaining mechanical properties, with the Composer A3 from Anisoprint.

Unique Composite Fibre Coextrusion (CFC) technology allows the printing of continuous carbon fibre directly into a 3D printed part, significantly increasing part strength when compared with printing polymers alone.

Anisoprint ProM IS 500

This industrial 3D printer by Anisoprint makes 3D manufacturing easier, faster, stronger and cheaper using high strength components, capable of printing high-performance polymers with Anisoprint\'s composite fibre co-extrusion technology.

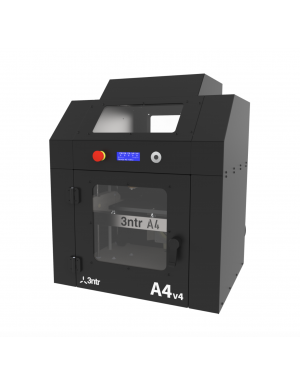

3ntr A4v4

The A4v4 by 3ntr is the ultimate dual nozzle 3D printer with expert precision in a compact design. The A4v4 is available in either a 2 or 3 nozzle setup, customisable to your printing needs.

LuxCreo iLux Pro Dental

The LuxCreo iLuxPro Dental printer is the highest-performing option for all dental laboratories and practices. Its DLP technology and ergonomic design make it a powerful ally for practitioners who wish to innovate in their field and provide increasingly effective dental parts without compromise.