Free lifetime remote support on all products

Ask us about our discounts for education

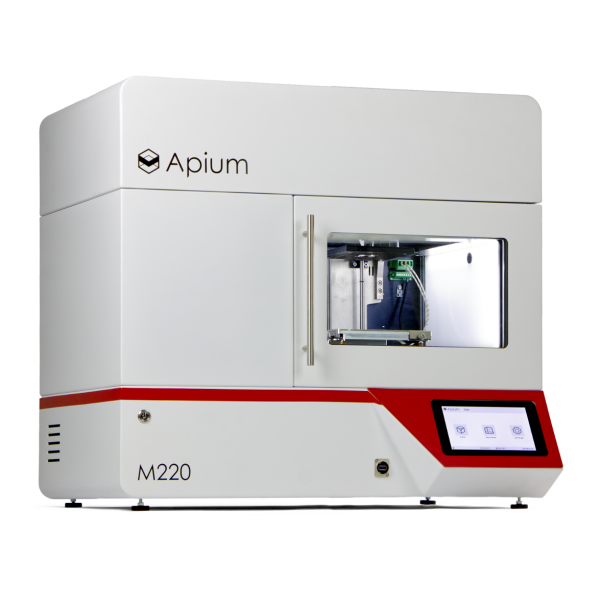

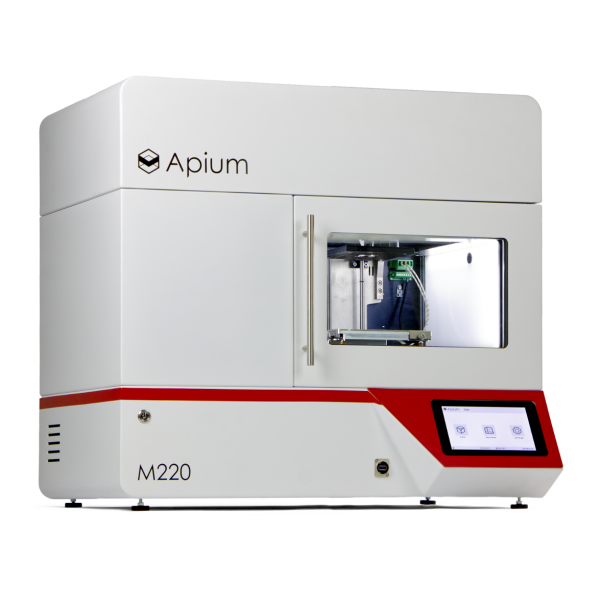

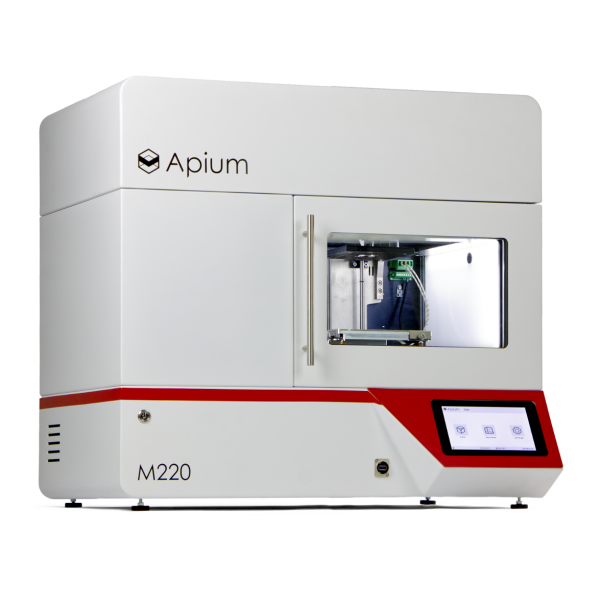

Apium M220 is ideal for producing patient specific implants and prosthetics at a reduced cost without effecting the biocompatibility and sterilisation of PEEK. Use radiological imaging data to produce complex geometries, 3D print and sterilise the parts in hours ready for en-vivo applications.

Radiology scan data

CAD of geometry to be 3D printed

Final PEEK 3D printed part ready for implant

Sterile Printing Environment- Hot air filtration system analyses the part geometry and adapts the heating power, ensuring optimum energy input is achieved. Filtered air flow enclosing the part allows for a contamination free build area.

Medically Compatible- Specially developed Apium extruder has a four times higher feed force than previous models. All machine components that come into contact with the 3D printing material are medically compatible

Biocompatible Filaments- Materials and filaments were tested in cooperation with Evonik for biocompatibility. Allowing medical devices up to class III to be manufactured from PEEK

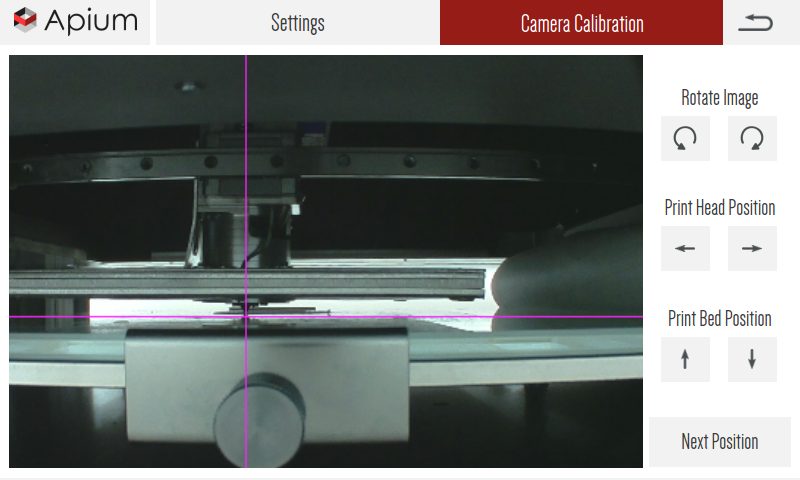

Featuring specially designed software that comes integrated into the M220. The control software is optimised to process high performance polymers and is designed to be easy to use. Perform tasks such as, manage jobs and check your printer status.

Integrated Camera System to monitor the build progress

Integrated, easy to use software. Featuring service and maintenance functions, allowing you to manage any issues and run the printer daily.

Integrated Software specially designed to process high performance polymers

Monitored Printing Process- Integrated camera with temperature recording monitors the entire printing process. If deviation occurs the printer can independently intervene

Integrated Software- Manage print jobs and check printer status easily by using the specially created web interface application. Easily access printer settings from the printer touchpad

Reproducibility- Achieve consistent part quality with the integrated calibration routines. The software will automatically notify you of any maintenance work needed and provide a step-by-step procedure

Technical Support & Documentation- iMakr will train you on your 3D printer and provide polymer information. All documentation relating to printer parameters and process are available via PDF, there is a secure user management system meaning you can prevent any unwanted access