Meet The Makrs: UCL School of Pharmacy

The world of 3D printing is expansive. There are so many different uses for the technology that stretch across industries such as architecture, dental, jewellery design and more, allowing for innovators and creative thinkers to dream up and make incredible projects.

In order to keep you up to date on all the advancements and varied applications for 3D printing, we’ve come up with the Meet The Makr Series. The series will explore Makrs from all types of disciplines to tell you a bit more about how they’re using 3D printers they’ve purchased from iMakr in everyday life as well as showcase some of the exciting ways that 3D printing has been able to change the way these Makrs do things.

This first installment will take a look at the UCL School of Pharmacy.

When UCL School of Pharmacy’s Senior Lecturer Stephen Hilton got started with 3D printing, he never turned back. UCL has been using 3D printing for quite some time now, across all areas and disciplines and even opening an on campus Fab Lab for students to come in and create. However one of the department’s Stephen has seen noticeable development in is the sciences, specifically chemistry within UCL’s School of Pharmacy.

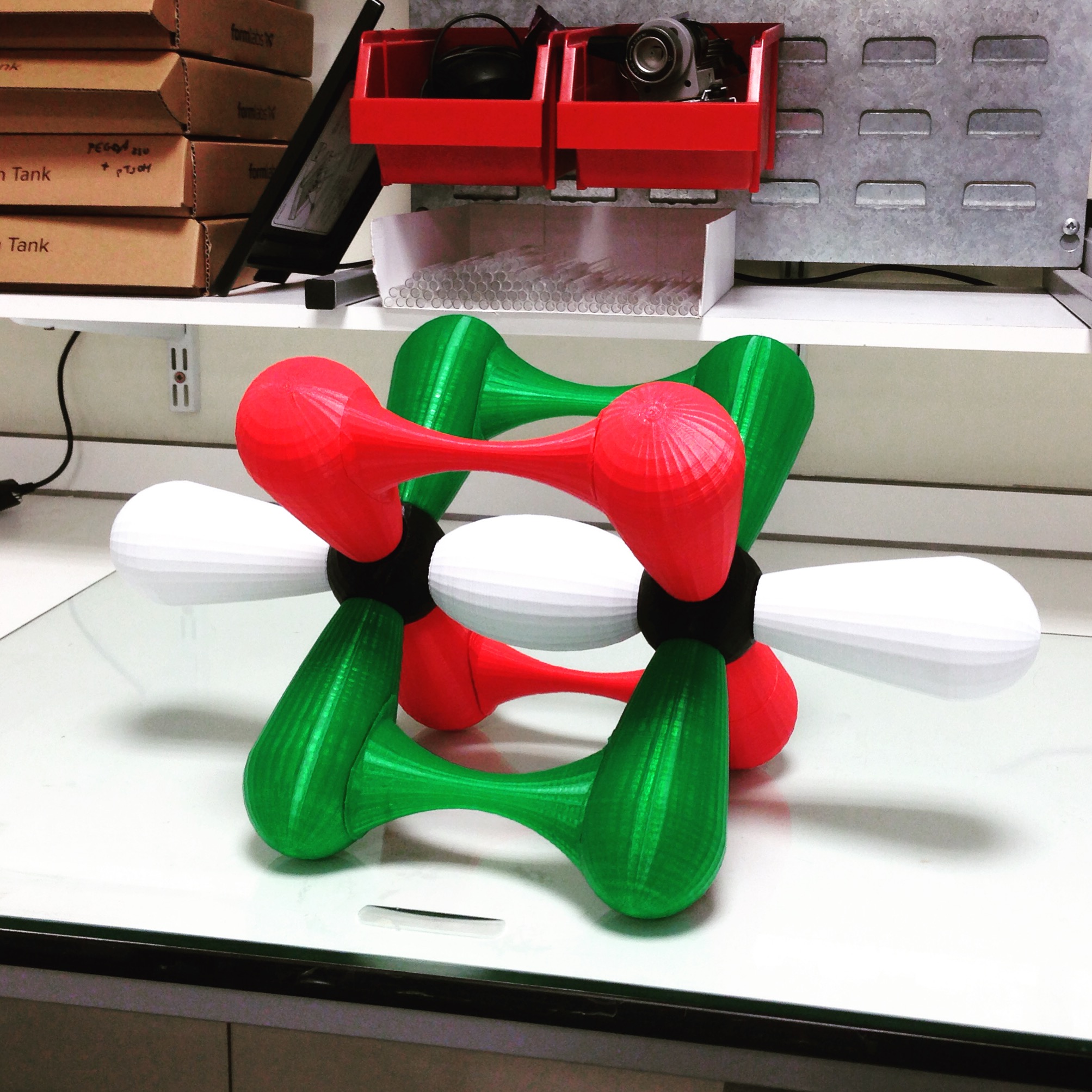

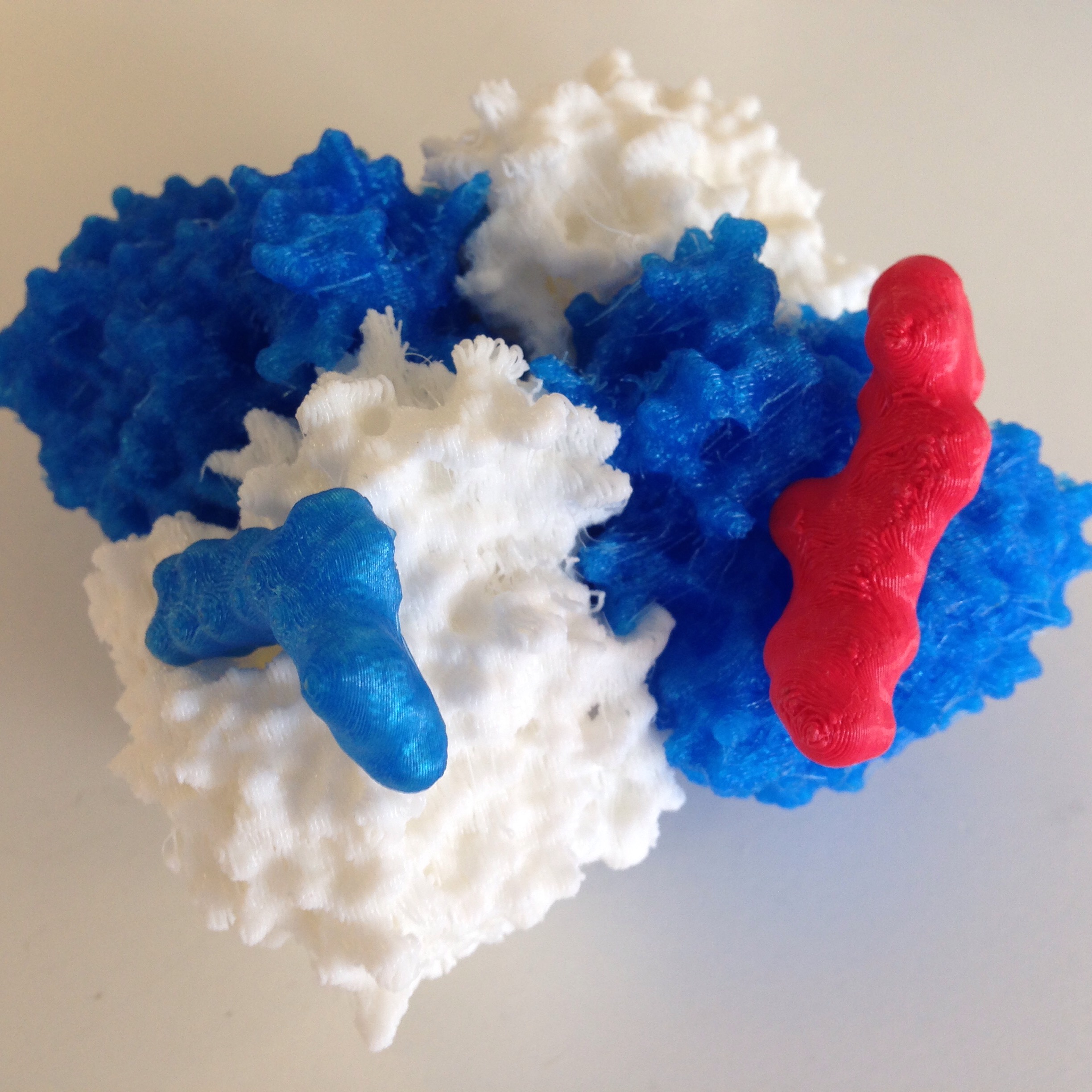

Chemistry is a science that looks at the composition, structure, properties and change of matter. A very visual science, 3D printing has drastically changed the way in which students research, develop medicines and learn the science as a whole. Mr Hilton says that 3D printing has been integrated into the first year program at the school because of the improved learning capabilities. Using printers from iMakr like Ultimaker, Stephen has been able to create brain models based off MRI scans, orbital models, molecular structures, etc which allows students to actually see and touch the items that he lectures about. Mr.Hilton says that this kinesthetic interaction makes the basic principles easier to digest as students can see how the molecules interact and better grasp how it all works. This was something that was harder to do before they implemented 3D printing into the course.

Experiments have also been able to move along a lot faster and save the university money. When working in the lab, you need specific materials that require you to wait until they come in before you can start testing. 3D printing allows the UCL School of Pharmacy students to bypass this - they’re able to make equipment for experiments on site quickly and at a fraction of the cost. They have loads of machines at their labs to produce pieces such as NMR tube holders, flask holders, clips, laser supports, slicing chambers, microelectrode holders, oxygenation chambers, slide staining chambers and more. Overall, Hilton says that they have saved thousands just by making things themselves and the best part is, the students can have what they need in order to start tinkering around with new research ideas immediately and get more insight into how an experiment comes together.

3D printing has also made research and product development grow in new ways at the school. Making things like low temperature reactors and implantable polymers students can now run one experiment 10 different ways within a day. For example, it traditionally takes a bit of time to create a chemical flow reactor but with a 3D printer on-hand, the process is sped up and students can instantly create as many flow reactors as needed for a given experiment. With 3D printing, they aren’t forced to look at a problem one way, they are free to be creative and try various solutions as they have an ample supply of research materials on hand to run the test again and again to come up with new medicines and research techniques. A few of the items they have been able to make as a result of their research include wound healing 3D scanned dressing for patients, chemotherapy implant devices and mobile phone spectroscopy devices.

Another cool fact about 3D printers at the UCL School of Pharmacy - it spawned a startup called 3D Synthesis. Springing forth from the laboratories at UCL, 3D Synthesis aims to provide novel custom reactors and catalytic devices to the chemical industries. Using 3D printed concepts, the startup is able to produce chemically resistant polymers that can be used on small scale, batch scale and flow chemistry.

Stephen Hilton sees the future of science, drug development and medicine overall changing for the better with 3D printing. Opening up his world as well as that of his students, they are able to take their scientific research a step further and do some really impressive work.

To see what these Makrs are doing regularly, check out Stephen Hilton’s Instagram - @hiltonlab!

Comments

Leave your comment