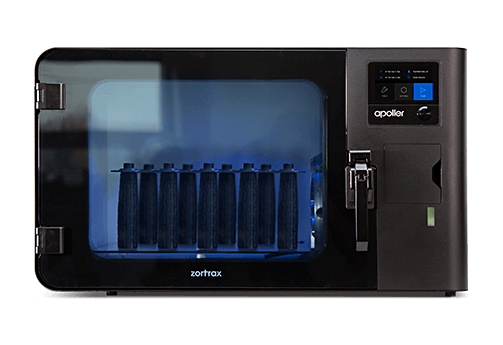

Automatic post-processing with the Zortrax desktop smart vapor smoothing device. Achieve the look of an injection moulded part from your FDM prints with the industrial performance. Smart Vapor Smoothing technology evenly smooths out all surfaces including all complex geometries and interlocking or movable parts. Ideal for small to medium production runs.

Kostenloser lebenslanger Remote-Support für alle Produkte

Fragen Sie uns nach unseren Bildungsrabatten

Automatic post-processing with the Zortrax desktop smart vapor smoothing device. Ideal for low to medium production runs. Achieve the look of an injection moulded part from your FDM prints with the industrial performance managed by the proprietary algorithms.

Print- Print parts on any FDM, FMM or LPD 3D Printer. Smooth- Place parts in the chamber and select the smoothing option. Relax- After 3 hours your parts are ready!

Smart Vapor Smoothing technology evenly smooths out all surfaces including all complex geometries and interlocking or movable parts. This is achieved by the automatic management of temperature, pressure and solvent concentration in the smoothing chamber. See below for a part before Apoller vapor smoothing and after.

The vapors are circulated upwards to evenly coat the parts. The Apoller Smart Vapor Smoother uses less solvent for any fragile or intricately detailed parts to ensure they remain intact. Once its finished, the condensation system retrieves the excess solvent for reuse.

Speed and ease of use- Fully automated smoothing process with machine set up taking only 3 hours.

SVS technology- Smart Vapor Smoothing is the Zortrax proprietary technology for automatic vapor smoothing.

Consistent results- All parts are evenly smoothed time and time again. With no limitations on geometry.

Compatibility- Acetone and MEK are used to smooth models produced on FDM, FFF, LDP 3D printers in ABS, HIPS or ASA based filaments.